The other business end of the horn utilizes a massive 4” 99.5% pure beryllium diaphragm. We chose beryllium (#4 on the Periodic Table of Atomic Elements) as it is one of the lightest metals and has one of the highest melting points among the light metals – 2,348.6 degrees F or 1287 degrees C!

The other business end of the horn utilizes a massive 4” 99.5% pure beryllium diaphragm. We chose beryllium (#4 on the Periodic Table of Atomic Elements) as it is one of the lightest metals and has one of the highest melting points among the light metals – 2,348.6 degrees F or 1287 degrees C!

To geek out a little more, beryllium’s modulus of elasticity (or ratio of the stress to the strain!) is about one-third greater than steel, making it ideal for forming into a dome. Beryllium is nonmagnetic and even resistant to concentrated nitric acid. It also has superior thermal conductivity and resists oxidation in air in normal temperatures.

But, perhaps most important of all, unlike other materials commonly used, beryllium dissipates vibrational energy (aka sound) very, very quickly. It is quite the opposite of a church bell, it hardly rings at all.

So, when used as a diaphragm in a compression driver the sound reproduction is incredibly pure.

Acoustic Properties of Beryllium

Acoustic Properties of Beryllium

Beryllium is widely used for a variety of special applications which utilize one or more of beryllium’s unique combination of properties including:

- High stiffness to density ratio

- Good strength to density ratio

- High heat capacity and thermal conductivity

- High atomic scatter cross-section and low absorption cross-section

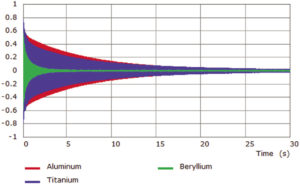

If you strike three identical tuning forks of Aluminum, Titanium, and Beryllium, you will hear decaying tones like those recorded and shown below.

You will notice the different frequencies, or pitches, at which they ring and the different durations of each tone. As we will show, these differences are due to the material properties of each fork.

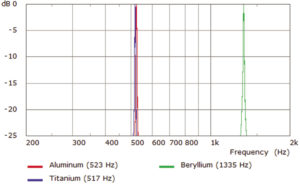

If we look at the Fourier Transform of those tones (below), we see the frequencies at which each tuning fork rings. Though much lower, these frequencies are analogous to those at which a speaker diaphragm of each material will begin to resonate or break-up. Beryllium rings at a frequency about 2.5x higher than aluminum and titanium (musically, this is more than an octave higher!). By analogy, if your 1” aluminum tweeter dome resonates at 22 kHz, then you can expect a similar beryllium tweeter to ring at over 50 kHz! Truextent Genuine Beryllium allows you to take full advantage of the extended bandwidth of today’s high-resolution audio.

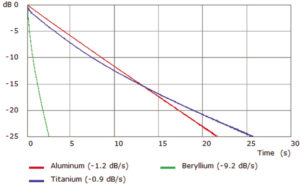

Also, we can use an Energy-Time Curve to see the loudness of each tone over time (below). This makes an easy calculation of the decay rate (dB/s) which tells us how well-damped each material is, or how quickly it will stop ringing. Note that Beryllium stops much faster than either Aluminum or Titanium, which ring for a very long time and are still audible after even 30 seconds!

The moral of this story is: If you want a good tuning fork (or dinner bell), use Titanium or Aluminum, but if you want a good speaker diaphragm, use Beryllium.

Our thanks to Materion Brush Inc. for the above data.

For more information: www.materion.com/truextent , or simply download https://materion.com/-/media/files/electrofusion/a_truextent_info/ttb002_tuningforks.pdf